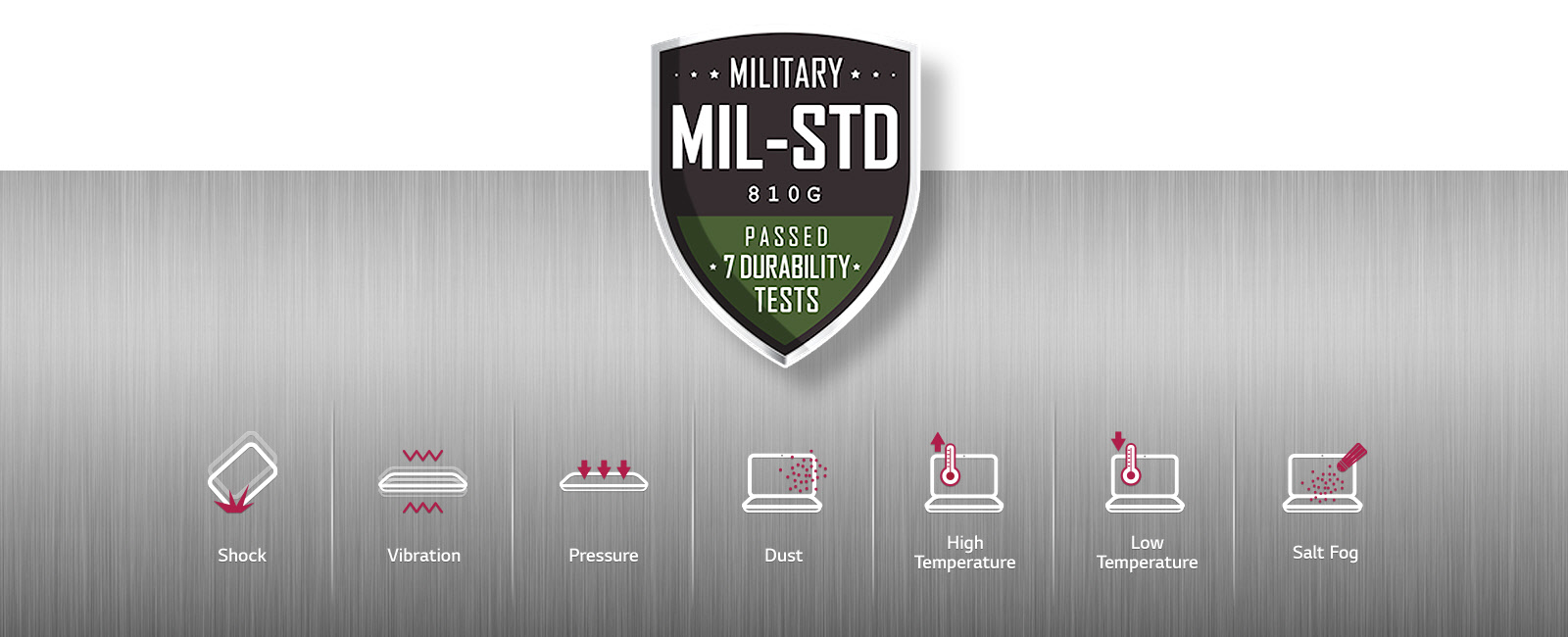

The US military standard MIL-STD-810G certification test, the US military standard MIL-STD-810G does not refer to a test item. The military equipment environmental test standard GJB 150A is adapted from the US military standard mil-std-810g. It covers the reliability test of climatic environment and mechanical environment, and is more stringent than other common environmental tests of electronic equipment, such as iec60068 and GB / t2423. The main users who meet the MIL-STD-810G standard of the United States are the military, police, telecommunication engineering, construction sites, outdoor measurement and other users who need to work outdoors. The working environment of these users is vulnerable to collision, rain, sand and dust, resulting in equipment damage. In addition to shockproof, waterproof, fall resistant and dust-proof, it can also be installed in field vehicles for use. The standard has been widely used by military and police personnel in Europe, Japan, Singapore, Europe, Malaysia and other places.

The procedures and test methods of MIL-STD-810G include:

1. Defining the sequence, duration and equipment life cycle level of environmental factors;

2. Developing analysis and testing standards suitable for the equipment and environmental life cycle;

3. Evaluating the performance of the equipment in the life cycle of environmental factors;

4. Defining the design, raw materials, manufacturing process, packaging technology, and maintenance methods of the equipment

5. The consistency of demonstration equipment and contract requirements.

The implementation of MIL-STD-810G is supervised by three service agencies, namely, the U.S. air force, the U.S. Army, and the U.S. Navy. As the executive agency leading standardization activities or preparatory activities, the US Army test and Evaluation Command (ATEC) maintains the functional operation of standards under the guidance of the Department of defense Standardization Program Organization (DSP), and provides technical support for standards for the Department of defense. The scope and purpose of MIL-STD-810G standard covers a wide range of environmental conditions, mainly including: high altitude, low pressure, high and low temperature, including temperature shock (including storage state and working state test), rain (including wind blowing test and freezing rain test), humidity, mold, salt spray corrosion, dust, explosive gas, liquid leakage, acceleration, impact and transportation impact, radiation Vibration and random vibration. MIL-STD-810G standard describes the environmental management and a series of engineering implementation process in detail, which is of great value to the reliability design and environmental adaptability design of the system. The military equipment procurement process includes the factors affecting the equipment procurement process in the service cycle. The document does not require specific design or test specifications, but describes the environmental testing process which is of great reference value for system material design, and the test methods of materials related to system performance.

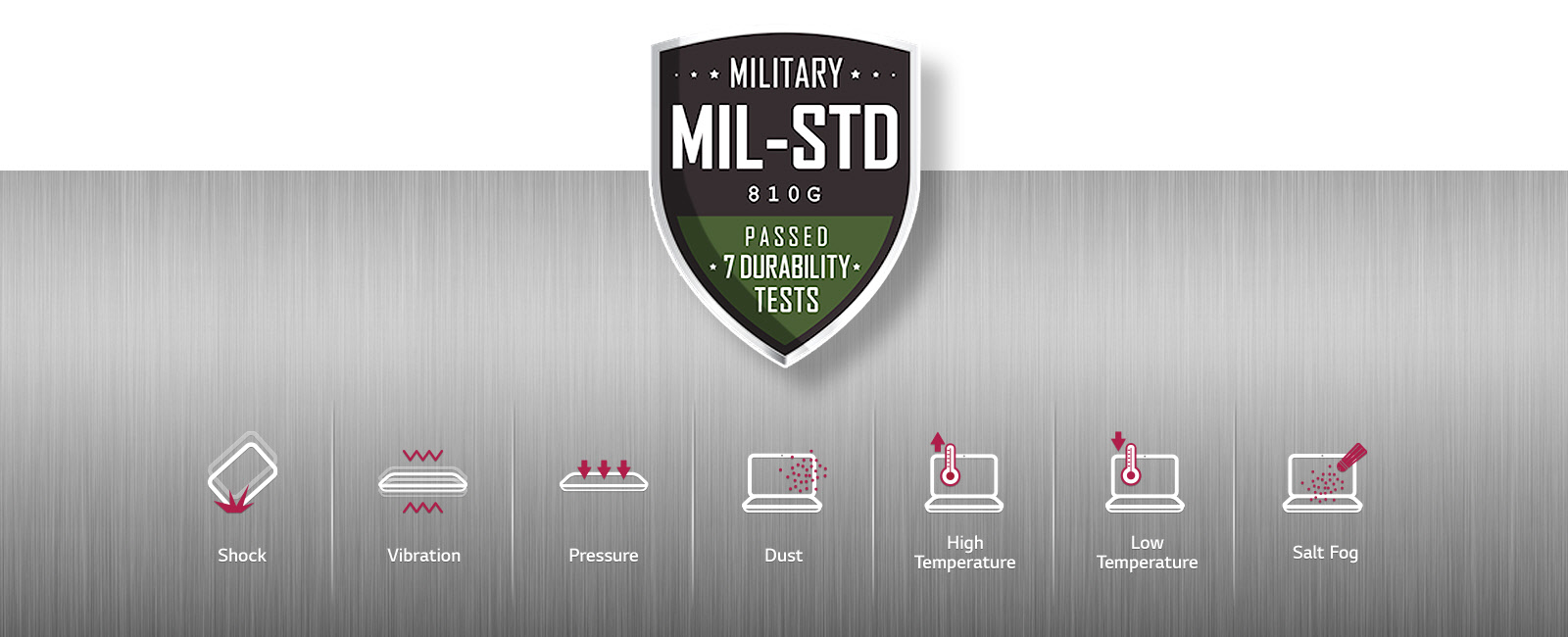

The US military standard MIL-STD-810G certification test, the US military standard MIL-STD-810G does not refer to a test item. The military equipment environmental test standard GJB 150A is adapted from the US military standard mil-std-810g. It covers the reliability test of climatic environment and mechanical environment, and is more stringent than other common environmental tests of electronic equipment, such as iec60068 and GB / t2423. The main users who meet the MIL-STD-810G standard of the United States are the military, police, telecommunication engineering, construction sites, outdoor measurement and other users who need to work outdoors. The working environment of these users is vulnerable to collision, rain, sand and dust, resulting in equipment damage. In addition to shockproof, waterproof, fall resistant and dust-proof, it can also be installed in field vehicles for use. The standard has been widely used by military and police personnel in Europe, Japan, Singapore, Europe, Malaysia and other places.

The procedures and test methods of MIL-STD-810G include:

1. Defining the sequence, duration and equipment life cycle level of environmental factors;

2. Developing analysis and testing standards suitable for the equipment and environmental life cycle;

3. Evaluating the performance of the equipment in the life cycle of environmental factors;

4. Defining the design, raw materials, manufacturing process, packaging technology, and maintenance methods of the equipment

5. The consistency of demonstration equipment and contract requirements.

The implementation of MIL-STD-810G is supervised by three service agencies, namely, the U.S. air force, the U.S. Army, and the U.S. Navy. As the executive agency leading standardization activities or preparatory activities, the US Army test and Evaluation Command (ATEC) maintains the functional operation of standards under the guidance of the Department of defense Standardization Program Organization (DSP), and provides technical support for standards for the Department of defense. The scope and purpose of MIL-STD-810G standard covers a wide range of environmental conditions, mainly including: high altitude, low pressure, high and low temperature, including temperature shock (including storage state and working state test), rain (including wind blowing test and freezing rain test), humidity, mold, salt spray corrosion, dust, explosive gas, liquid leakage, acceleration, impact and transportation impact, radiation Vibration and random vibration. MIL-STD-810G standard describes the environmental management and a series of engineering implementation process in detail, which is of great value to the reliability design and environmental adaptability design of the system. The military equipment procurement process includes the factors affecting the equipment procurement process in the service cycle. The document does not require specific design or test specifications, but describes the environmental testing process which is of great reference value for system material design, and the test methods of materials related to system performance.

Email us >

Email us >